UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 10-K

(Mark One)

x ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF

THE SECURITIES EXCHANGE ACT OF 1934

For the fiscal year ended December 31, 2013

¨ TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES

EXCHANGE ACT OF 1934

For the transition period from ____________ to ____________

Commission file number 0-24277

BLACK DIAMOND, INC.

(Exact name of Registrant as specified in its Charter)

| Delaware | 58-1972600 |

| (State or Other Jurisdiction | (I.R.S. Employer Identification No.) |

| of Incorporation or Organization) | |

| 2084 East 3900 South, Salt Lake City, Utah | 84124 |

| (Address of Principal Executive Offices) | (Zip Code) |

(801) 278-5552

(Registrant's telephone number, including area code)

Securities registered pursuant to Section 12(b) of the Act:

| Title of each class | Name of each exchange on which registered |

| Common Stock, par value $.0001 per share | NASDAQ Global Select Market |

Securities registered pursuant to Section 12(g) of the Act:

None

(Title of class)

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act. YES ¨ NO x

Indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or Section 15(d) of the Exchange

Act. YES ¨ NO x

Indicate by check mark whether the registrant: (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the Registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days. YES x NO ¨

Indicate by check mark whether the registrant has submitted electronically and posted on its corporate Web site, if any, every Interactive Data File required to be submitted and posted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit and post such files). YES x NO ¨

Indicate by check mark if disclosure of delinquent filers pursuant to Item 405 of Regulation S-K is not contained herein, and will not be contained, to the best of Registrant's knowledge, in definitive proxy or information statements incorporated by reference in Part III of this Form 10-K or any amendment to this Form 10-K. x

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer or a smaller reporting company. See the definitions of “large accelerated filer,” “accelerated filer” and “smaller reporting company” in Rule 12b-2 of the Exchange Act:

Large accelerated filer ¨ Accelerated filer x Non-accelerated filer ¨ Smaller reporting company ¨

Indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act) YES ¨ NO x

The aggregate market value of the voting stock and non-voting common equity held by non-affiliates of the Registrant at June 30, 2013 was approximately $213.8 million based on $9.39 per share, the closing price of the common stock as quoted on the NASDAQ Global Select Market.

As of February 26, 2014, there were 32,478,247 shares of common stock, par value $0.0001, outstanding.

DOCUMENT INCORPORATED BY REFERENCE

Portions of our Proxy Statement for the 2014 Annual Meeting of Stockholders to be filed with the Securities and Exchange Commission within 120 days of the Registrant's 2013 fiscal year end are incorporated by reference into Part III of this Annual Report on Form 10-K.

| 1 |

INDEX

BLACK DIAMOND, INC.

| Page | ||

| PART I | ||

| Item 1. | Business | 3 |

| Item 1A. | Risk Factors | 15 |

| Item 1B. | Unresolved Staff Comments | 26 |

| Item 2. | Properties | 26 |

| Item 3. | Legal Proceedings | 26 |

| Item 4. | Mine Safety Disclosures | 27 |

| PART II | ||

| Item 5. | Market for Registrant’s Common Equity, Related Stockholder Matters and Issuer Purchases of Equity Securities | 28 |

| Item 6. | Selected Financial Data | 30 |

| Item 7. | Management’s Discussion and Analysis of Financial Condition and Results of Operations | 32 |

| Item 7A. | Quantitative and Qualitative Disclosures About Market Risk | 42 |

| Item 8. | Financial Statements and Supplementary Data | 44 |

| Item 9. | Changes in and Disagreements With Accountants on Accounting and Financial Disclosure | 71 |

| Item 9A. | Controls and Procedures | 71 |

| Item 9B. | Other Information | 73 |

| PART III | ||

| Item 10. | Directors, Executive Officers and Corporate Governance | 74 |

| Item 11. | Executive Compensation | 74 |

| Item 12. | Security Ownership of Certain Beneficial Owners and Management and Related Stockholder Matters | 74 |

| Item 13. | Certain Relationships and Related Transactions, and Director Independence | 74 |

| Item 14. | Principal Accounting Fees and Services | 74 |

| PART IV | ||

| Item 15. | Exhibits and Financial Statement Schedules | 75 |

| Signature Page | 81 | |

| Exhibit Index | 82 | |

| 2 |

PART I

ITEM 1. BUSINESS

Overview

Black Diamond, Inc. (which may be referred to as “Black Diamond,” “Company,” “we,” “our,” or “us,”) is a global leader in designing, manufacturing, and marketing innovative active outdoor performance equipment and apparel for climbing, mountaineering, backpacking, skiing, cycling, and a wide range of other year-round outdoor recreation activities. Our principal brands include Black Diamond®, Gregory™, POC™ and PIEPS™ and are targeted not only to the demanding requirements of core climbers, skiers and cyclists, but also to the more general outdoor performance enthusiasts and consumers interested in outdoor-inspired gear for their backcountry and urban activities. Our Black Diamond®, Gregory™, POC™ and PIEPS™ brands are iconic in the active outdoor, ski and cycling industries and linked intrinsically with the modern history of the sports we serve. We believe our brands are synonymous with the performance, innovation, durability, and safety that the outdoor and action sports communities rely on and embrace in their active lifestyle.

We offer a broad range of products including: technical apparel, rock-climbing equipment (such as carabiners, protection devices, harnesses, belay devices, helmets, and ice-climbing gear), technical backpacks and high-end day packs, lifestyle packs, trekking poles, headlamps and lanterns, and gloves and mittens. We also offer advanced design helmets for skiing, mountain and road cycling, body armor, goggles for skiing and mountain biking, eyewear, skis, ski poles, ski bindings, ski boots, ski skins and ski safety products, including avalanche transceivers, shovels, and probes. We distribute our products through a network comprised primarily of leading independent specialty retailers, specialty chains such as Recreational Equipment, Inc. (“REI”), independent global distributors selling to specialty retail, and direct-to-consumer through our websites and wholly-owned retail stores. Our products are sold in North America, Europe, Asia, and the rest of the world in approximately 50 countries, with international sales representing approximately 61% of our sales for the year ended December 31, 2013.

Our heritage dates back to 1957 when Chouinard Equipment Ltd. pioneered the market for durable, precise, and reusable pitons — devices used to ascend or protect oneself in the event of a fall in the sport of big wall rock climbing. Over the next thirty years, Chouinard Equipment expanded to design and manufacture all kinds of equipment for rock climbing and mountain, canyon, and crag activities. In 1989, our President and Chief Executive Officer Peter Metcalf co-founded Black Diamond Equipment, our predecessor company, to purchase the business and assets of Chouinard Equipment, a company he ran starting in 1982. In our 56 year heritage, we have developed a track record of gear innovations that has changed the nature of climbing, freeride and telemark skiing, and mountaineering. By extension, our history and brands have become synonymous with the sports in which we participate. The genesis of the current Black Diamond, Inc. was through the May 2010 acquisition of Black Diamond Equipment, Ltd. (which may be referred to as “Black Diamond Equipment” or “BDEL”) and Gregory Mountain Products, Inc. (which may be referred to as “Gregory Mountain Products” or “GMP”) by Clarus Corporation, a public company. Clarus Corporation, incorporated in Delaware in 1991, was renamed Black Diamond, Inc. in January 2011. In July 2012 we acquired POC Sweden AB and its subsidiaries (collectively, “POC”) and in October 2012 we acquired PIEPS Holding GmbH and its subsidiaries (collectively, “PIEPS”).

Market Overview

Our business and brands are benefiting from the convergence of function and fashion in the outdoor and athletic apparel, footwear, and equipment space. We believe consumer purchase decisions are driven by both a need for functional products with distinctive aesthetics and a desire to create a particular lifestyle perception. This confluence and consumer behavior can be seen in a number of highly successful lifestyle brands including Lululemon, Under Armour, The North Face, and Nike. Primary growth drivers in our business include innovative products that provide a higher level of protection, performance and or comfort, an increased awareness in health and wellness, the desire to own functional products that are aesthetically pleasing, and the continued success and exposure of our key retail partners including REI, Mountain Equipment Co-op, and Backcountry.com. The outdoor products marketplace, both domestically and internationally, is highly fragmented. Specialty brands, particularly throughout Europe, hold respectable market share relative to larger competitors. We see this fragmentation as an opportunity for a leader to emerge, particularly in the more technical categories. We believe that our strong relationships in the specialty retail channel and our expanding online presence provides us with a competitive advantage and the opportunity for significant growth.

Competitive Strengths

At Black Diamond we live and breathe the adventure sports that we represent and approach business like we approach our sporting passions, where there is precious little room for error. We believe the following strengths differentiate us from our competitors, allowing us to take advantage of the large and growing market in which we participate:

| 3 |

Authentic Portfolio of Iconic/Lifestyle Brands. We believe that our brands are iconic among devoted active outdoor adventurers, skiers and cyclists with a strong reputation for innovation, style, quality, design, safety and durability. Our brands also appeal to everyday customers seeking high quality, outdoor-inspired lifestyle products for outdoor or urban and suburban living. The authenticity of our brands is reinforced by our selective distribution strategy focused on specialty retail stores that we believe are the most influential stores within the outdoor recreation and active lifestyle communities. We believe our brands transcend age, culture and geography, and our paradigm-changing products define their respective product categories. Our focus on innovation, safety and style differentiates us from our competitors and positions Black Diamond to address the growing market for outdoor recreation equipment and active lifestyle products.

Recent Awards. In January 2014, at successive trade shows in North America and Europe, the Company’s brands won over a dozen awards, bringing to light both individual brand innovation and efficient partnership across the Company’s platforms. The debut of JetForce technology, the first avalanche airbag system to use electronically controlled jet-fan inflation, was awarded “Gear of the Show” at Outdoor Retailer Winter Market in Salt Lake City, Utah by Outside magazine, Men’s Journal, GearJunkie.com and GearInstitute.com. JetForce technology represents Black Diamond’s commitment to the snow safety category and is expected to be available in specific backpacks from Black Diamond, PIEPS and POC in fall 2014.

At ISPO Munich, Black Diamond, PIEPS, and POC collected five awards in the ski, outdoor and accessories categories. Of these five awards, Black Diamond Equipment received two ISPO Gold Awards, one for its Jetforce technology and one in the accessory apparel category for Cohaesive Embedded Components.

At the Snowsports Industry America (SIA) show, held in Denver, Colorado, Outside magazine awarded POC with “Gear of the Show” for its Skull Orbic Comp H.I. MIPS helmet. Skiing Magazine also awarded the JetForce Technology with its “Hot Gear” award.

Global Brands.

Black Diamond Equipment: Black Diamond Equipment products and apparel are designed for climbers, mountaineers and skiers as well as aspirational outdoor enthusiasts. We focus on innovation and performance, and we strive to deliver products that epitomize high quality and durability. Black Diamond® branded products received over forty international awards in 2013 for design and innovation in outdoor and snowsports and broad based media, honoring Black Diamond Equipment skis, ski boots, tents, headlamps, backpacks, climbing equipment, and the notable Magnetron carabiner. In 2014, Black Diamond Equipment won ISPO awards specifically for the Carbon Megawatt ski and two ISPO Gold for the JetForce technology and Cohaesive embedded technology in apparel.

Gregory Mountain Products: Gregory Mountain Products designs and manufactures premier technical backpacking, running, and mountaineering products and accessories, as well as outdoor-inspired lifestyle bags for urban and suburban living. Gregory™ packs are world-renowned for setting performance standards in backpacks; they are noted for innovative design, ergonomic, and comfortable fit, and an obsession with quality, comfort, and durability. Select recent awards for Gregory Mountain Products include National Geographic Magazine’s Gear of the Year 2012 for the Cache 22 rolling travel bag and a coveted ISPO Award 2013 for the Targee 32 ski mountaineering backpack. In spring 2013, Gregory Mountain Products introduced a new line of trail running hydrations systems available in lightweight backpacks, lumbar packs, and handheld bottle systems.

POC: Based in Stockholm, Sweden, POC’s mission is to save lives and reduce the consequences of injury. It is a developer of protective gear for action sports. POC produces and distributes advanced-design helmets, body armor, goggles, eyewear, gloves, and apparel for action or “gravity sports,” like skiing, snowboarding, and cycling, with a particular emphasis on safety and protection. POC, renowned for its design aesthetic, research, and innovation, is the recipient of numerous industry awards, including the Ski Industry Association and US Ski Team’s DesRoches Award for innovation in marketing and outstanding support and promotion of the US Ski Team and USSA club programs. Additionally, POC won ISPO awards in the ski category for the new multi-impact Orbic helmet and Lids goggles. POC’s patented technologies continue to set new standards for construction, material combinations, and engineering for personal protection. In 2014, POC won two ISPO awards for the POC Skull Orbic Comp H.I. MIPS multi impact helmet and POC ICEdot Crash Sensor.

| 4 |

PIEPS: Headquartered in Lebring, Steiermark, Austria, PIEPS is widely recognized as an innovator and technology leader in avalanche safety equipment. PIEPS offers a focused range of premium avalanche safety products, including transceivers and probes, shovels, related equipment, and packs. PIEPS is the official safety partner of the Association of Austrian Mountain and Ski Guides. PIEPS played a key partnership role with Black Diamond Equipment in development of the new JetForce avalanche airbag technology platform that debuted at the January Outdoor Retailer Winter Market tradeshow, ISPO Munich and Snowsports Industry Association tradeshow.

Product Innovation and Development Capabilities. We have a long history of technical innovation and product development, with over 100 patents and patents pending worldwide and hundreds of new product introductions since 1989 and before. Our employees’ passion and intimacy with our core outdoor activities fosters new and innovative ideas, which we believe provides a significant advantage that will drive our Company and industry to new levels. Our Salt Lake City headquarters, nestled in the Wasatch Mountains, with such a vibrant user community, provides the ideal backdrop for our employees, many of whom are high-level performance athletes in these sports themselves, to test and refine our new products. We endorse several top athletes who evaluate our products in the field, providing valuable feedback and suggestions to our designers. In recent years, we have developed many innovative products that have revolutionized the active outdoor space including: a new line of freeride ski boots; trekking poles with FlickLock® technology; Z-Poles that can fold to one-third their size; the AvaLung® backpack; the Magnetron magnetically locking carabiner; the Vapor climbing helmet, one of the lightest climbing helmets on the market; and brighter, more compact and lighter-weight headlamps. We believe that our POC™ brand has brought a higher level of safety to ski racers and cyclists with patented protective gear technologies. We seek to design products that enhance our customers’ personal performance, safety, and comfort as they participate in the activities we serve. We integrate quality assurance and quality control teams throughout the entire design process to maintain the quality, integrity, and safety that our brands are known for. We believe that our vertically integrated design and development process and enthusiastic employee base provide us with a unique competitive advantage to continue to drive future innovation for our Company and the industries we serve.

Diversified Portfolio by Brand, Product, Geography and Channel. Our business is highly diversified across brands, products, geographies, and channels. We operate a multi-brand platform with Black Diamond®, Gregory™, POC™, and PIEPS™ branded products spanning 34 single product categories addressing four primary categories of mountaineering, climbing, skiing, and wheels. No single product category accounts for more than 15% of annual sales. This provides seasonal diversification with a balance of sales across both the fall/winter and spring/summer sports seasons. Our brands are truly global with approximately 61% of our sales for the year ended December 31, 2013 generated outside the United States in approximately 50 countries. We have a highly diversified customer base and sell products in approximately 10,000 retail locations, including independent and specialty stores, our websites at www.blackdiamondequipment.com, www.gregorypacks.com and www.pocsports.com, and other retail locations. We believe that our brand, product, geographic, and distribution channel diversity allows us to maximize the reach of our brand portfolio while reducing the risk associated with any single brand, product category or point of distribution.

Scalable Global Operating Platform. We have developed a highly scalable global platform of manufacturing, sourcing, quality assurance, distribution, IT, and back office capabilities. We manufacture approximately 20% to 25% of our proprietary products in-house, which we believe is cost competitive and helps us maintain our competitive advantage over our peers. We also have a global network of high-quality strategic partners, many of whom we have had relationships with for over ten years, from which we source the remaining approximately 75% to 80% of our manufactured products. We have in-house quality assurance teams in our facilities in Salt Lake City, Zhuhai, China, and in Bataan, Philippines, the site of a large portion of our third party manufacturing, allowing for real-time testing and development. Our back-office functions, including supply chain management, warehousing, sourcing, and finance, run on our global ERP platform. Our scalable global operating platform provides for separate front-end operations, which allows our individual brands to remain unique to our customers and to retain brand ethos while benefitting from our global scale and back-end infrastructure. Additionally, we believe that we can efficiently insert new brands into the existing structure, as we have done with the integration of Gregory Mountain Products, POC, and PIEPS.

Core Values Deeply Rooted in Organization. Our Company was founded with the vision of being one with the sports we serve, absolutely indistinguishable from them. Our mission is to profitably design, manufacture, and bring to market innovative and technical products of high quality, high performance, and exemplary durability that are targeted toward our primary customers – climbers, mountaineers, off-piste skiers, as well as ski racers and cyclists. We define ourselves on a five-pillar founding construct: passion and intimacy, innovation, efficiency, value and service, and style. We are guided by our ten commitments, which include pursuing market leadership, maintaining a global presence, supporting specialty retailing, and developing a sustainable competitive advantage. Our employees have a tight bond and shared enthusiasm for the active outdoors. The sports we collectively engage in have athleticism, adventure and commitment at their core, and our team shares these qualities throughout the organization. We take pride in our efforts to support conservation, education, and recreation groups that are on the frontlines of protecting and preserving the wild lands we love and depend on. These shared core values enable us to attract and retain like-minded, highly motivated employees with passion for the active outdoors.

| 5 |

Experienced and Incentivized Senior Management Team. Our senior management team has been involved in the operation, acquisition, and integration of several successful companies. Peter Metcalf, our lead-founder, President and Chief Executive Officer for over 24 years, boasts a lifetime of active participation in outdoor sports and a compelling track record in the outdoor/ski products industry. We are also supported by the skills and collective experience of Warren B. Kanders, our Executive Chairman, and Robert R. Schiller, our Executive Vice Chairman, who have substantial experience working together in managing operations and building public companies through strategic acquisitions and organic development, notably at Armor Holdings, Inc. Mr. Kanders and Mr. Schiller have worked together for the past 17 years. We have assembled a proven and talented global management team led by Mr. Metcalf. We have historically experienced very low management turnover, as our executives share a passion for outdoor recreation and an active lifestyle, and possess substantial experience in product development, marketing, and merchandising. The members of our Board of Directors and our executive officers, including Messrs. Kanders, Metcalf, and Schiller, are substantial stockholders of the Company and beneficially own approximately 32% of our outstanding common stock as of February 26, 2014, which we believe aligns the interests of our Board of Directors and our executive officers with that of our stockholders.

Growth Strategy

We intend to achieve sustainable, profitable growth by expanding organically in each of our historical product lines and our new apparel line and in our recently acquired businesses. Our goal is to become the number one premium active outdoor gear and lifestyle company.

Continue to service and grow existing retail accounts. Since our inception, we have developed strong relationships with our key retail partners through a mutual respect and admiration for the sports we serve. As the outdoor retail industry expands in terms of both sales and store count, we believe that we are well-poised to capitalize on this growth opportunity. Through our various corporate initiatives, including our retail introduction of a technical apparel line, the extension of our existing product portfolios, an emphasis on brand awareness and visual merchandising, we plan to grow and service our existing retail accounts as well as foster new relationships.

Introduce New Product Technologies and Expand Existing Brands Into New Categories. We believe our new product extensions present opportunities, through both technological innovation and expansion into new categories. We have a long history of technical innovation, introducing hundreds of new products and growing sales at a 15% compound annual growth rate since 1989. We expect to continue this product innovation and see the potential for continued double-digit growth driven by future product innovation as well as increasing participation in the active outdoor sports that we serve. For instance, the Black Diamond Equipment Vapor helmet sandwiches a sheet of Kevlar and carbon rods in between expanded polystyrene (EPS) foam to create a helmet with exceptional venting and weighing 186 grams. Further innovation specific to climbing is evident with the new Camalot X4 camming protection devices which recently won Climbing Magazine’s Editor’s Choice with its sleek, flexible, and durable design.

We plan to expand our business into both adjacent and complementary product categories, including outdoor technical apparel. In 2012, we introduced to the trade our first apparel line which was in retail stores in fall 2013. We believe that apparel represents the single largest growth opportunity for our brands and that our intimate understanding of the desired fit, performance, style, and aesthetics of products for the sports we serve will help us to be successful in this initiative. We have expanded our product offerings and grown our sales through innovation in ski boots, gloves, trekking poles, helmets, and headlamps and believe apparel represents a logical progression for our outdoor brands. We also believe that footwear may be another natural extension of our product offerings and expect to seek to enter that market in the future.

Broaden Distribution Footprint and Elevate Brand Profile. We believe there is a significant opportunity to expand our brand presence and penetration outside of the U.S. market. We believe that the European Alpine market is currently significantly larger than the U.S. market and is highly fragmented by country, with no clear leader across Europe. We have been able to gain market share by emphasizing our Black Diamond® and Gregory™ brands, positioning them as global brands with American roots and POC™ and PIEPS™ as global brands with Scandinavian and European roots, respectively. Furthermore, we plan to seek to bring some of our international distributors in-house, as we did with Gregory Mountain Products’ Japanese distribution, to seek to increase the number of doors we sell through and drive higher sales through new and existing doors. In spring of 2014, we expect to transition some key POC territories from independent distributor status to that of sales agency served from our expanded European and North American distribution and service operations. In addition, in spring 2014, POC is expected to launch a merchandising initiative at retail to support its entry into the race and road riding market.

We believe that our presence in Asia, further solidified with the acquisition of Gregory Mountain Products’ distribution assets, also represents a significant growth opportunity. Gregory Mountain Products’ primary business in Asia is currently in Japan, where the brand enjoys a premium position as an iconic American brand. We believe that this success in Japan is driving business in Hong Kong, China, South Korea, and other key Asian markets. Additionally, through the combination with Black Diamond Equipment, Gregory™ branded products gained immediate access to the European market through Black Diamond Equipment’s legacy distribution platform. Likewise, we expect that our POC™ and PIEPS™ brands will derive similar benefits in specific geographic markets.

| 6 |

Expand Our Operating Margins. We believe opportunities exist to increase our margins to be more in-line with our outdoor peers. Over the past several years, we have made significant investments in our global operating platform and we are currently investing in our apparel initiative. A primary driver of our expected margin expansion will include leveraging these investments as our sales continue to grow. Additionally, we expect to see margin expansion as we shift our sales mix to higher margin products and bring several of our distributors in-house.

Our Brands

Our Black Diamond®, Gregory™, POC™, and PIEPS™ brands represent the pinnacle of innovation, quality, and performance to our customers in the active outdoor industry. All have rich histories that we believe transcend age, ethnicity, and geography. All have reputations as pioneers in the industry, designing and manufacturing gear that has changed the history of their collective sports.

Black Diamond®

Founded in 1989, Black Diamond Equipment is devoted to fostering the enthusiasm and dreams necessary to design and manufacture what we believe to be the best climbing and skiing gear in the world. Black Diamond Equipment’s roots date back to 1957, when Chouinard Equipment Ltd. first manufactured rock climbing equipment. From its inspired beginning in 1957, Black Diamond Equipment has grown into a global company with operations on three continents. Since then, Black Diamond Equipment’s innovative gear designs have set the standards in numerous areas, including rock climbing, backcountry skiing, mountaineering, ice climbing, and trekking. This is the result of dedication, desire, and passion on the part of Black Diamond Equipment’s team of people who are climbers, skiers and mountaineers.

In 1992, Black Diamond Equipment responded to the needs of telemark skiers in their quest for more downhill ski control by introducing the T1, the world’s first plastic telemark ski boot in conjunction with Scarpa. Today, Black Diamond Equipment offers a full line of skis, boots, poles, and bindings for expert skiers and beginners alike. More recently, after considerable testing and extensive research, Black Diamond Equipment unveiled the AvaLung®, and later, AvaLung-equipped packs (essential tools for backcountry safety) that are designed to allow the user to breathe under snow if buried in an avalanche.

Black Diamond Equipment also introduced the Turbo ExpressTM Ice Screw and CobraTM Ice Tool, which are perfectly matched to the attitudes and needs of today’s extreme ice climbs and mixed routes. For rock climbers, Black Diamond Equipment designed and built the world’s first wire-gate carabiner, the HotWireTM. Stronger, lighter, and easier to clip than previous carabiners, the HotWire proved that a seemingly basic design like a carabiner could be improved to meet the continuing demands of the sport.

Today, our commitment to the founding principles of Black Diamond Equipment remains as unwavering as ever. After 56 years, Black Diamond Equipment has grown to include operations in the United States, Europe, and Asia. We strive to serve the spirit for all the sports we serve, and the sports’ values and goals, past, present, and future. Black Diamond Equipment’s intimacy with skiing, climbing, and mountaineering is proven by winning more than 40 awards in 2013 for climbing, skiing and mountaineering equipment. Specific products include the X4TM camming device, RavenTM ice axe, ReVoltTM headlamp, BDV Hoody apparel, Spy gloves, multiple skis and the Factor MX boots in 2013 from titles such as National Geographic, Men’s Journal, Outside, Skiing, Powder, and Backcountry magazines. Similarly, the Magnetron carabiner won accolades from Popular Science, Outside, Men’s Journal, Red Dot (Germany) iF Design Awards (Germany), Climbing, Urban Climber, and National Geographic.

Gregory™

Founded in 1977, Gregory Mountain Products designs and builds backpacks for mountaineers and hikers, as well as for everyday customers seeking outdoor-inspired lifestyle bags for urban and suburban living. Gregory Mountain Products sets the standard in the backpacking and mountaineering industry with its reputation for durability, fit, and performance. Our robust Gregory™ branded product line spans such diverse uses as trail running, mountain biking, expedition mountaineering, trekking, fast-packing, day hiking, multi-day backpacking, travel, and lifestyle packs. Gregory™ branded backpacks are in use on the Appalachian Trail, the Pacific Crest Trail, mountaineering expeditions, trail runs around the globe, family car camping, and airports everywhere.

Gregory Mountain Products was the first manufacturer to understand the benefits of building backpacks in differing frame sizes and the first to devise a scale that measured torso lengths to achieve a correct match between customer and pack size. In addition, Gregory Mountain Products was the first to offer a range of waist belts and shoulder harnesses in different sizes (in both men’s and women’s models). Gregory Mountain Products also pioneered a waist belt system that automatically adjusts to fit different hip angles, which improves load transfer into the lumbar region of the back to improve its overall comfort when carrying weight. Over fifteen years ago, Gregory Mountain Products began developing a line of urban lifestyle packs for the market in Asia, based on the heritage of the brand and its California origins. The introduction of these lifestyle packs extended Gregory Mountain Product’s customer base significantly beyond the technical product category.

| 7 |

The guiding principal at Gregory Mountain Products remains as strong today as 36 years ago when the company first began making packs – that a properly fitted backpack leads to considerably more enjoyment for the hiker, backpacker, and mountaineer to follow their pursuits. This focus and drive has resulted in numerous awards for pack design from such diverse media outlets like Outside Magazine’s Gear of the Year for the Border 35 travel pack, ISPO 2013 award for the Targhee backcountry ski pack and Outside Travel Award for the Alpaca rolling duffle. In spring 2013, Gregory Mountain Products debuted a new trail running hydration system in addition to new offerings in technical backpacks and lifestyle travel.

POC™

Founded in 2004, POC produces and distributes to 27 countries advanced-design helmets, body armor, goggles, eyewear, gloves, and apparel for action or “gravity sports,” like skiing, snowboarding, and cycling, with a particular emphasis on safety and protection.

POC, renowned for its design aesthetic, research, and innovation, is the recipient of numerous recent industry awards in 2013, including the Ski Industry Association and US Ski Team’s DesRoches Award for innovation in marketing and outstanding support and promotion of the US Ski Team and USSA club programs. Additionally, POC won ISPO awards in January 2014 in Helmets for the POCTM Skull OrbicTM Comp H.I. MIPS, and Accessories for collaboration with ICEdot crash sensors. POC’s patented technologies continue to set new standards for construction, material combinations, and engineering for personal protection.

PIEPS™

Founded in 2006, with roots dating back to 1972, PIEPS is recognized as an innovator and technology leader in avalanche safety equipment. PIEPS offers a focused range of premium avalanche safety products, including transceivers and probes, shovels, safety equipment, and packs. PIEPS is the official safety partner of the Association of Austrian Mountain and Ski Guides. PIEPS played a key partnership role with Black Diamond Equipment in development of the new JetForce avalanche airbag technology platform that debuted at the January 2014 Outdoor Retailer Winter Market tradeshow, ISPO Munich 2014 and Snowsports Industries America 2014 tradeshows.

Our Products

We have developed a reputation for designing, manufacturing, and distributing products considered to be both innovative and dependable in their respective market niches. Our commitment to designing innovative, durable, and reliable products that enhance our customers’ capabilities, comfort, and safety in their outdoor endeavors will remain our hallmark and mission. In addition to function, we believe our products’ unique aesthetic appearance is another hallmark that distinguishes us in the outdoor marketplace. Our products have won over 40 awards from within the industry groups, from design media and consumer media including Alpinist, Backcountry, Backpacker, Climbing, Consumers Digest, Freeskier, National Geographic Adventure, Men’s Journal, Outside, Popular Science, Powder, Rock & Ice, Ski, and Skiing.

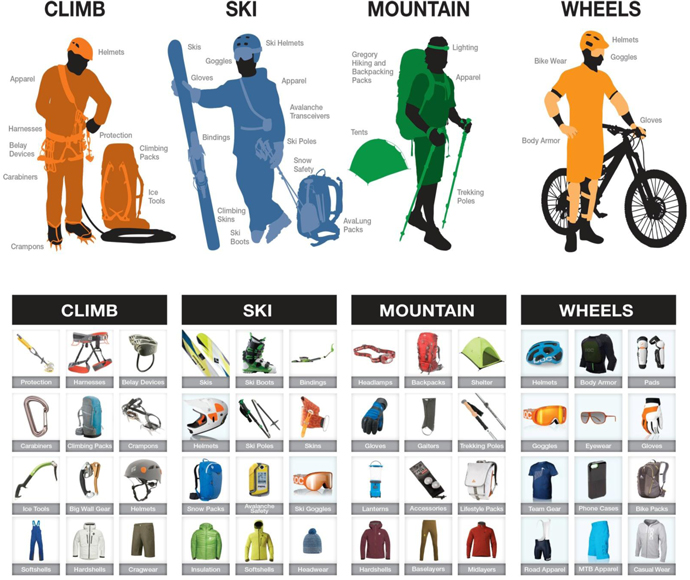

Our products span 34 single product categories and include a wide variety of technical outdoor equipment and lifestyle products for rock and ice climbers, alpinists, hikers, skiers, cyclists, outdoor enthusiasts, and travelers, providing seasonal diversification with a balance of sales across both the fall/winter and spring/summer sports seasons. We design many of our products for extreme applications, such as high altitude mountaineering, ice and rock climbing, mountain and road riding, as well as backcountry, freeride, alpine skiing, and race skiing. Generally, we divide our product offerings into the following four primary categories:

| · | Climb: Our climb line consists of technical equipment such as belay/rappel devices, bouldering products, carabiners and quickdraws, chalk, chalk bags, climbing packs, crampons, crash pads, harnesses, climbing packs, crampons, technical and mountaineering ice axes, ice and rock protection devices, a bouldering line of technical apparel, and various other climbing accessories. Our climb line represented approximately 23% of our sales during the year ended December 31, 2013. |

| · | Ski: Our ski line consists of technical apparel, helmets, AvaLung avalanche backpacks, winter packs for skiing and snowboarding, bindings, body armor, boots, goggles, poles, skis, skins, snow gloves, snow packs, and avalanche safety devices, including transceivers, probes, and shovels. Our ski line represented approximately 26% of our sales during the year ended December 31, 2013. |

| · | Mountain: Our mountain line consists of mountaineering backpacks for backpacking, expeditions, alpinism, endurance sports, and an array of day uses in both the outdoor and urban environments. We also offer lifestyle packs, travel luggage, gaiters, gloves, headlamps, lights, tents, trekking poles, and various other hiking and mountaineering accessories. Our mountain line represented approximately 48% of our sales during the year ended December 31, 2013. |

| 8 |

| · | Wheels: Our wheels line consists of helmets, body armor, goggles, eyewear, gloves, hydration packs, and apparel for mountain and road cycling. Our wheels line represented approximately 3% of our sales during the year ended December 31, 2013. |

Product Design and Development

We are a company founded on innovation and believe that our success is uniquely tied to our ability to consistently introduce new product innovations across all of our brands. We have a long history of technical innovation and product development, introducing hundreds of new products since 1989, with over 100 patents and patents pending worldwide. In recent years, we have developed many innovative products that we believe have revolutionized the active outdoor space. For example, in 2008, we introduced a new line of freeride ski boots featuring revolutionary ski/walk performance. We have also been an innovator in trekking poles, introducing the first poles with FlickLock® technology that allow a single-handed locking mechanism and Z-Poles that can fold to one-third their size. Our innovations in lighting have re-defined the headlamp niche by taking simple components and combining them in a unique manner. The AvaLung® backpack is a unique safety device that is designed to help adventurers survive an avalanche by increasing the amount of time a person can breathe while trapped under snow. The effectiveness of the Avalung® was tested by doctors and scientists, who published their results in the Journal of the American Medical Association in 2000.

POC has quickly established its reputation for sleek design and safety in the helmet and protection ranks in gravity sports such as skiing, snowboarding, and cycling. POC™ was one of the first helmet brands to use MIPS (Multi-directional Impact Protection Systems) to combat rotational impact which is common in most action sports falls. Similarly, PIEPS™, is a brand name synonymous with avalanche beacons.

| 9 |

Each person involved in our product design and development process shares a passion for the active outdoor sports that we serve and strives to develop and iterate new ideas. We regularly rotate our designers and engineers across product categories as we believe this fosters creative inspiration. We conduct our product research and design activities at our locations in Salt Lake City, Utah, Stockholm, Sweden, and Lebring, Austria and conduct product evaluations at our offices located near Basel, Switzerland.

Our employees’ passion and intimacy with our core outdoor activities helps foster new and innovative ideas. Our in-house research and development teams engage in all stages of planning, conceptualization, design, development, commercialization, and production. Our vertically integrated process allows our design team to conduct market research, brainstorm, plan product lines, prototype, and review designs before turning them over to our engineers to begin the development and production of the product. Quality assurance and control are a key component of our development process and products undergo rigorous in-house and field-testing at regular stages of the process. Our Salt Lake City headquarters, in the Wasatch Mountains, with such a vibrant user community, provides the ideal backdrop for our employees to test our new products. Likewise, our European locations provide quick access to their products’ intended environments. Additionally, the athletes who we endorse evaluate our products in the field and provide valuable feedback and suggestions to our designers. We believe this collaborative interaction helps preserve the brand image, authenticity, quality, and performance.

We are typically able to bring new products from concept to market in approximately 24 to 36 months depending upon the technology integration and complexity of the product. We work simultaneously on product lines for the four subsequent selling seasons.

We expense research and development costs as incurred. As of December 31, 2013, we had 70 employees dedicated to research and development and have spent approximately $20.3 million in connection with research and development activities over the last three calendar years. This does not include amounts incurred by POC and PIEPS during this entire time, which we acquired during 2012, and both have dedicated teams to their respective significant research and development activities.

Customers

We market and distribute our products in approximately 50 countries, primarily through independent specialty stores and specialty chains, including premium sporting goods and outdoor recreation stores and consumer catalogs, in the United States, Canada, South America, New Zealand, Europe, Asia, Australia, and Africa. Outside of North America, Europe and Japan, we also sell our products through independent global distributors into specialty retail stores. In addition, our GregoryTM branded products are sold through licensed Gregory retail stores in Tokyo, Japan, Seoul, South Korea, and Taiwan. We also sell our products directly to customers through our wholly-owned Black Diamond retail store in Salt Lake City, Utah, POC retail store in Chamonix, France, as well as online at www.blackdiamondequipment.com, www.gregorypacks.com and www.pocsports.com.

We have long-standing relationships with our specialty retail customers and maintain our commitment to continue to sell through this channel. We have a highly diversified customer base and sell products in approximately 10,000 retail locations, with the bulk of our business being done through independent retailers.

Our end users include a broad range of consumers, including mountain climbers, winter outdoor enthusiasts, backpackers and campers, cyclists, ski racers, top endurance trail runners, and outdoor-inspired consumers. Such consumers demand high-quality, reliable, and well-designed products to enhance their performance and safety in a multitude of outdoor activities in virtually any climate. We expect to leverage our user intimacy, engineering prowess, and design ability to expand into related technical product categories that target the same demographic group and distribution channels.

During 2013, REI accounted for approximately 12% of our sales. The loss of this customer could have a material adverse effect on us.

Sales and Marketing

We deploy our sales force by geographic region with a focus on providing our products to a broad spectrum of active outdoor enthusiasts, from core rock climbers and mountaineers to first-time skiers and cyclists. Within each of our brands, we strive to create a unique look and image for our products.

In 2011, we re-strategized our marketing strategy with the goal of creating a truly seamless, "consumer-centric" approach that complements our strong relationships with our specialty retail partners. As part of this, Black Diamond is engaging on a limited basis outside partners and global retailers to build well-branded and retail-appropriate branding kits, fixturing, and window kits. As a regular part of our marketing program, we use various promotions, on both a local and global level, as well as public relations campaigns to promote our brands.

For the past 20 years, we’ve established and maintained ongoing relationships with professional athletes who excel at the sports of climbing, mountaineering, skiing, and cycling. These top athletes evaluate our products in the field with demanding use and under punishing conditions, providing valuable feedback and suggestions to our designers. They also promote our products at events, tradeshows and while in the field pursuing their sports. Finally, we believe they are invaluable at establishing brand authenticity with customers.

| 10 |

Our award-winning online marketing campaign is designed to increase consumer demand and awareness by connecting directly with our customer base as well as potential customers through www.blackdiamondequipment.com, www.gregorypacks.com, www.pocsports.com, www.pieps.com, and a variety of social media outlets. Our online flagship marketing vehicles are www.blackdiamondequipment.com and www.pocsports.com, where we seek to give consumers in depth insight into our research and technology efforts, including helmet and protection design in the POC Lab, educate consumers, drive excitement for our products, and provide a memorable ecommerce experience for core athletes and beginners alike.

This past year we have focused heavily on evolving our approach to social media and online marketing (email, paid and organic search) with the goal of increasing qualified visitation to our websites. The broader goal is and remains to offer our customer a best-in-class, intuitive, consistent, two-way conversation that enables them to interact with our brands in a manner consistent with the expectations set by the very products that have founded the Company. Part of this effort includes the development and nurturing of social media outlets as stand-alone Black Diamond® brand outposts. These outposts engage our most enthusiastic brand advocates with product updates, information regarding our sponsored athletes, their accomplishments and in turn, better help us create a sense of brand community while reinforcing brand identity. This past year has seen Black Diamond grow its Facebook "Likes" by 39% to 142,000, and the progress in our online marketing programs enabled the online business to achieve growth of 25% year-over-year.

Our social media strategy is to lever the strength of our growing fan bases as extremely well-targeted segments for brand-rich communications. We will seek to increase Facebook fan bases for all of the Company’s brands, curating original content uniquely suited to our communities, Facebook advertising and the launch of Facebook-exclusive interactive applications and raffles. We are seeking to increase our Twitter followers by posting unique and timely content, including product updates and information as well as posts regarding our sponsored athletes and their endeavors.

Manufacturing, Sourcing, Quality Assurance and Distribution

Manufacturing

The story of Black Diamond Equipment is based on our history as a manufacturer of precisely engineered rock climbing equipment. As we have grown in both capacity and capability, we have increased our reliance on automation but still maintain the notion of craftsmanship melded to engineering as a driving force for what we manufacture. We operate three manufacturing facilities. The first, located in Salt Lake City, Utah, specializes in the fabrication of highly engineered and tightly controlled components and a short-list of finished products. We have made significant investments in sophisticated, automated, and custom built equipment, including cold and hot-forging, laser cutting, heat-treating, CNC turning, machining and milling, and tool making. Our research and development and design teams are primarily situated at this facility.

The second facility, located in Zhuhai, China, specializes in finishing operations and assembly for the vast majority of products that we manufacture ourselves. This operation includes very sophisticated, automated, multi-station, internet accessible testing equipment and one of only a handful of clean, close-loop, automated anodizing installations in southeast China. These two facilities operate in tandem and as extensions of each other, representing a true core competency. In 2012, we established a wholly-owned, state-of-the-art ski manufacturing factory adjacent to our Zhuhai, China operations.

Our third facility is our small, but efficient, PIEPS managed transceiver assembly facility, attached to PIEPS’ headquarters in Leibring, Austria.

We manufacture approximately 20% to 25% of our products, including nearly all climbing hard goods, in our facilities in the United States and Asia. The remaining approximately 75% to 80% of our products are also manufactured to our specifications in third-party, independently-owned facilities primarily located in China and the Philippines. We keep employees and agents on-site or via regular visits at these third-party, independently owned facilities to ensure that our products are manufactured to meet our specifications. While we do not maintain a long-term manufacturing contract with those facilities, we believe that our long-term relationships with them will help to ensure that a sufficient supply of goods built to our specification are available in a timely manner and on satisfactory economic terms in the future.

In 2006, we established Black Diamond Sporting Equipment (ZFTZ) Co. Ltd. (“Black Diamond Asia”), a wholly-owned subsidiary of Black Diamond Equipment, in southeast China. Black Diamond Asia’s facility in southeast China is a Black Diamond Equipment-managed 100,000 sq. ft. facility that is operated and staffed by our employees. Each piece of equipment is tested to the same degree at the Black Diamond Asia facility as it is at our Salt Lake City facility. Each of those facilities relies on identical, thoroughly documented systems and procedures to ensure consistent quality and safety for every piece of gear we put our name on. Black Diamond’s Salt Lake City and Zhuhai manufacturing and distribution facilities are ISO 9001–2008 certified by an independent certifying agency. Both facilities are audited yearly by an independent certifying agency to ensure that Black Diamond’s quality management system meets the requirements of ISO 9001–2008 and to ensure that Black Diamond’s certified products meet the necessary certification requirements.

| 11 |

Sourcing

We source raw materials and components from a variety of suppliers. Our primary raw materials include aluminum, steel, nylon, corrugated cardboard for packaging, electrical components, plastic resin, urethane, and various textiles, foams, and fabrics. The raw materials used in the manufacture of our products are generally available from numerous suppliers in quantities sufficient to meet normal requirements.

We source packaging materials both domestically as well as from sources in Asia and Europe. We believe that all of our purchased products and materials could be readily obtained from alternative sources at comparable costs.

Quality Assurance

Quality assurance at Black Diamond has two primary functions:

| · | The first is to ensure that the product that we design and develop is manufactured to meet or exceed Black Diamond’s own standards and international regulatory standards. This involves creating inspection documentation, reviewing manufacturing processes with our various vendor-partners, and inspecting finished product to assure it meets the rigorous standards required by our customers. These activities take place globally, wherever product is manufactured. |

| · | The second function is to provide real and meaningful input to the new product development process. Quality assurance professionals interact closely with the design team and bring knowledge and expertise to the design process, ensuring that the products we bring to market truly meet the criteria established by the category director when a new product is envisioned. |

The engineering prowess of the quality assurance group (much like that of the manufacturing team) is a core competency that Black Diamond seeks to leverage across all product lines and brands.

Global Distribution

In addition to manufacturing in our Zhuhai facility, we also run our own global distribution and quality control operations. Having these functions located close to the source of much of our product allows us to aggregate, inspect, warehouse, and then distribute goods coming from an extremely diverse group of small to mid-size vendor partners. Our distribution model allows us to ship a broad cross-section of our product line in smaller quantities to our own global distribution centers and to those of our Independent Global Distributors (IGD) more frequently and at lower transportation and logistics costs.

Competition

Because of the diversity of our product offerings, we compete by niche with a variety of companies. Our products must stand up to the high standards set by the world’s elite mountain climbers, alpine skiers, adventurers, and cyclists. In the outdoor industry, quality and durability are paramount among these athletes who rely on our products to withstand some of the world’s most extreme conditions. In addition to extreme adventurers and racers, we believe all outdoor enthusiasts benefit from the high-quality standards of our products. We also believe our products compete favorably on the basis of product innovation, product performance, marketing support, and price.

The popularity of various outdoor activities and changing design trends affect the desirability of our products. Therefore, we seek to anticipate and respond to trends and shifts in consumer preferences by adjusting the mix of available product offerings by developing new products with innovative performance features and designs, and by marketing our products in a persuasive and memorable fashion to drive consumer awareness and demand. Failure to anticipate or respond to consumer needs and preferences in a timely and adequate manner could have a material adverse effect on our sales and profitability.

We compete with niche, privately-owned companies as well as a number of brands owned by large multinational companies, such as those set forth below.

| · | Climb: Our climbing products and accessories, such as belay devices, carabiners, and harnesses, compete with products from companies such as Arc’Teryx, Petzl, and Mammut. |

| · | Ski: Our skiing apparel, equipment and accessories, such as technical apparel, skis, ski bindings, poles, transceivers, and boots, compete with products from competitors such as Atomic, Arc’Teryx, Backcountry Access, Dynafit (Salewa), Dynastar (Lange), K2, Marker, Nordica, Ortovox, Rossignol, Salomon, Scarpa, Scott, and Volkl. |

| 12 |

| · | Mountain: Our mountaineering products, such as backpacks, trekking poles, headlamps, and tents, compete with products from companies such as Petzl, Mammut, Deuter, Kelty, Leki, Komperdell, Marmot, Mountain Hardwear, Mountainsmith, Osprey, Dakine, Sierra Designs, and The North Face. |

| · | Wheels: Our wheels products, such as helmets, body armor, goggles, eyewear, and gloves, compete with products from companies such as Giro, Smith, K2, Uvex, and Oakley. |

In addition, we compete with certain of our large wholesale customers who focus on the outdoor market, such as REI, Eastern Mountain Sports, Mountain Equipment Co-op and Decathlon, which manufacture, market and distribute their own climbing, skiing, and mountaineering products under their own private labels.

Intellectual Property

We believe our registered and pending word and icon trademarks worldwide, including the Black Diamond, Diamond "C" and Gregory logos, Black Diamond®, ATC®, Camalot®, Gregory™, AvaLung®, FlickLock®, Ascension™, Time is Life®, Hexentric®, Stopper®, Dawn Patrol™, Bibler®, "Use.Design.Build.Engineer.Repeat"™, POC™, and PIEPS™, create international brand recognition for our products.

We believe our brands have an established reputation for high quality, reliability, and value, and accordingly, we actively monitor and police our brands against infringement to ensure their viability and enforceability.

In addition to trademarks, we hold over 100 patents and patents pending worldwide for a wide variety of technologies across our product lines.

Our success with our proprietary products is generally derived from our “first mover” advantage in the market as well as our commitment to protecting our current and future proprietary technologies and products, which acts as a deterrent to infringement of our intellectual property rights. While we believe our patent and trademark protection policies are robust and effective, if we fail to adequately protect our intellectual property rights, competitors may manufacture and market products similar to ours. Our principal intellectual property rights include our patents and trademarks but also include products containing proprietary trade secrets.

We cannot be sure that we will receive patents for any of our patent applications or that any existing or future patents that we receive or license will provide competitive advantages for our products. While we actively monitor our competitors to ensure that we do not compromise the intellectual property of others, we cannot be sure that competitors will not challenge, invalidate or avoid the application of any existing or future patents that we receive or license. In addition, patent rights may not prevent our competitors from developing, using or selling products that are in similar product niches as ours.

Seasonality

Our products are outdoor recreation related, which results in seasonal variations in sales and profitability. On a calendar year basis, we generally experience our greatest sales in the first and second quarters for certain of our products, including rock climbing gear, body armor, eyewear, goggles, headlamps, helmets, lanterns, packs, trekking poles, and tents and in the third and fourth quarters for our technical apparel, ski, glove, avalanche safety, and ice climbing products. Sales of these products may be negatively affected by unfavorable weather conditions and other market trends. The fall/winter season represents approximately 56% of our sales while spring/summer represents approximately 44% of our sales.

Working capital requirements vary throughout the year. We fund our working capital through the use of our line of credit, which is classified as a long-term liability. Working capital increases during the first and third quarters of the year as inventory builds to support peak shipping periods and then decreases during the second and fourth quarters of the year as those inventories are sold and accounts receivable are collected, which cash collected is then used to pay down the outstanding amounts on the line of credit.

Environmental Matters

Our operations are subject to federal, state, and local environmental, health and safety laws and regulations, including those that impose workplace standards and regulate the discharge of pollutants into the environment and establish standards for the handling, generation, emission, release, discharge, treatment, storage, and disposal of materials and substances including solid and hazardous wastes. We believe that we are in material compliance with such laws and regulations. Further, the cost of maintaining compliance has not, and we believe in the future, will not have a material adverse effect on our business, consolidated results of operations, and consolidated financial condition. Due to the nature of our operations and the frequently changing nature of environmental compliance standards and technology, we cannot predict with any certainty that future material capital or operating expenditures will not be required in order to comply with applicable environmental laws and regulations.

| 13 |

Employees

As of December 31, 2013, we had 746 employees worldwide. None of our employees are represented by unions or covered by any collective bargaining agreements. We have not experienced any work stoppages or employee-related slowdowns and believe that our relationship with employees is satisfactory.

Executive Officers of the Registrant

The executive officers of our Company as of December 31, 2013 are as follows:

Warren B. Kanders, 56, our Executive Chairman, has served as one of our directors since June 2002 and as Executive Chairman of our Board of Directors since December 2002. Since 1990, Mr. Kanders has served as the President of Kanders & Company, Inc., a private investment firm principally owned and controlled by Mr. Kanders, which makes investments in and provides consulting services to public and private entities. From January 1996 until its sale to BAE Systems plc (“BAE Systems”) on July 31, 2007, Mr. Kanders served as the Chairman of the Board of Directors, and from April 2003 as the Chief Executive Officer, of Armor Holdings, Inc. (“Armor Holdings”), formerly a New York Stock Exchange-listed company and a manufacturer and supplier of military vehicles, armored vehicles, and safety and survivability products and systems to the aerospace and defense, public safety, homeland security, and commercial markets. Mr. Kanders received an A.B. degree in Economics from Brown University.

Robert R. Schiller, 51, has served as our Executive Vice Chairman since May 2010. Mr. Schiller served as Vice Chairman of the Board of Directors of Gregory Mountain Products from March 2008 until May 2010. From July 1996 until its sale to BAE Systems on July 31, 2007, Mr. Schiller served in a variety of capacities at Armor Holdings, including as a Director from June 2005, President from January 2004, Chief Operating Officer from April 2003, and Chief Financial Officer and Secretary from November 2000 to March 2004. Mr. Schiller graduated with a B.A. in Economics from Emory University in 1985 and received an M.B.A. from Harvard Business School in 1991.

Peter R. Metcalf, 58, has served as our President, Chief Executive Officer and director since May 2010. Mr. Metcalf served as the Chief Executive Officer and Chairman of the Board of Directors of Black Diamond Equipment since co-founding it in 1989 until the completion of the Company’s acquisition of Black Diamond Equipment in May 2010. He is a graduate of the University of Colorado, with a major in Political Science. He also earned a Certificate in Management from the Peter Drucker Center of Management.

Aaron J. Kuehne, 35, is our Chief Financial Officer, Secretary and Treasurer. Mr. Kuehne previously served as the Company’s interim Chief Financial Officer, in addition to serving as its Vice President of Finance, principal financial officer and principal accounting officer. Before joining the Company in September 2010, Mr. Kuehne served as the Corporate Controller of Certiport from August 2009 to September 2010. From July 2004 to August 2009, Mr. Kuehne served in various capacities with KPMG LLP, most recently as Audit Manager. Mr. Kuehne graduated with a Bachelor of Arts degree in Accounting from University of Utah – David Eccles School of Business in 2002 and with a M.B.A. degree from University of Utah – David Eccles School of Business in 2004.

Available Information

Our Internet address is www.blackdiamond-inc.com. We make available free of charge on or through our website our annual reports on Form 10-K, quarterly reports on Form 10-Q, current reports on Form 8-K, and amendments to those reports, and the proxy statement for our annual meeting of stockholders as soon as reasonably practicable after we electronically file such material with, or furnish it to, the Securities and Exchange Commission. Forms 3, 4 and 5 filed with respect to our equity securities under Section 16(a) of the Securities Exchange Act of 1934, as amended, are also available on our website. All of the foregoing materials are located at the ‘‘SEC Filings’’ tab under the section titled “Investor Relations.” The information found on our website shall not be deemed incorporated by reference by any general statement incorporating by reference this report into any filing under the Securities Act of 1933, as amended, or under the Securities Exchange Act of 1934, as amended, and shall not otherwise be deemed filed under such Acts.

Materials we file with the Securities and Exchange Commission may be read and copied at the Securities and Exchange Commission’s Public Reference Room at 100 F Street, Room 1580, N.E., Washington, D.C. 20549. You may obtain information on the operation of the Securities and Exchange Commission’s Public Reference Room by calling the Securities and Exchange Commission at 1-800-SEC-0330. The Securities and Exchange Commission also maintains a website that contains reports, proxy and information statements, and other information regarding issuers that file electronically with the Securities and Exchange Commission at www.sec.gov. In addition, you may request a copy of any such materials, without charge, by submitting a written request to: Black Diamond, Inc., c/o the Secretary, 2084 East 3900 South, Salt Lake City, UT 84124. The contents of the websites identified above are not incorporated into this Annual Report on Form 10-K.

| 14 |

ITEM 1A. RISK FACTORS

In addition to other information contained in this Annual Report on Form 10-K, the following risk factors should be carefully considered in evaluating our business, because such factors may have a significant impact on our business, operating results, liquidity and financial condition. As a result of the risk factors set forth below, actual results could differ materially from those mentioned in any forward-looking statements. Additional risks and uncertainties not presently known to us, or that we currently consider to be immaterial, may also impact our business, operating results, liquidity and financial condition. If any of the following risks occur, our business, operating results, liquidity and financial condition, and the price of our common stock, could be materially adversely affected.

Risks Related to Our Industry

Many of the products we sell are used for inherently risky mountain and outdoor pursuits and could give rise to product liability or product warranty claims and other loss contingencies, which could affect our earnings and financial condition.

Many of our products are used in applications and situations that involve high levels of risk of personal injury and death. As a result, we maintain a staff, including an in-house legal counsel, who focus on the appropriate disclaimers and markings and testing and seek to assure the quality and safety of our products. We stay current with the law to seek to provide thorough and protective disclaimers and instructions on all of our products and packaging. Furthermore, our technical climbing and avalanche safety equipment and our operations meet and are certified to International Personal Protective Equipment (PP) standards set by the EEC or ISO 9001 quality system standards. Failure to use our products for their intended purposes, failure to use or care for them properly, or their malfunction, or, in some limited circumstances, even correct use of our products, could result in serious bodily injury or death.

We remain exposed to product liability claims by the nature of the products we produce. Exposure occurs if one of our products is alleged to have resulted in property damage, bodily injury or other adverse effects. Any such product liability claims may include allegations of defects in manufacturing, defects in design, a failure to warn of dangers inherent in the product or activities associated with the product, negligence, strict liability, and a breach of warranties. Although we maintain product liability insurance in amounts that we believe are reasonable, there can be no assurance that we will be able to maintain such insurance on acceptable terms, if at all, in the future or that product liability claims will not exceed the amount of insurance coverage. Additionally, we do not maintain product recall insurance. As a result, product recalls or product liability claims could have a material adverse effect on our business, results of operations and financial condition.

As a manufacturer and distributor of consumer products, we are subject to the Consumer Products Safety Act, which empowers the Consumer Products Safety Commission to exclude from the market products that are found to be unsafe or hazardous. Under certain circumstances, the Consumer Products Safety Commission could require us to repurchase or recall one or more of our products. Additionally, laws regulating certain consumer products exist in some cities and states, as well as in other countries in which we sell our products, and more restrictive laws and regulations may be adopted in the future. Any repurchase or recall of our products could be costly to us and could damage our reputation. If we were required to remove, or we voluntarily removed, our products from the market, our reputation could be tarnished and we might have large quantities of finished products that we could not sell.

We spend substantial resources ensuring compliance with governmental and other applicable standards. However, compliance with these standards does not necessarily prevent individual or class action lawsuits, which can entail significant cost and risk. We do not maintain insurance against many types of claims involving alleged defects in our products that do not involve personal injury or property damage. As a result, these types of claims could have a material adverse effect on our business, results of operations, and financial condition.

Our product liability insurance program is an occurrence-based program based on our current and historical claims experience and the availability and cost of insurance. We carry both general and umbrella liability policies that insure us for product liability claims. The policy has a small retention, which enables us to manage and control our product liability claims. Historically, product liability awards have not exceeded our individual per occurrence self-insured retention. We cannot assure you, however, that our future product liability experience will be consistent with our past experience.

A substantial portion of our sales and gross profit is derived from a small number of large customers, none of whom are contractually obligated to continue buying our products. The loss of any of these customers could substantially reduce our profits.

A customer accounts for a significant portion of revenues. In the year ended December 31, 2013, REI accounted for approximately 12% of sales. Sales are generally on a purchase order basis, and we do not have long-term agreements with any of our customers. A decision by any of our major customers to decrease significantly the number of products purchased from us could substantially reduce sales and have a material adverse effect on our business, financial condition and results of operations. Moreover, in recent years, the retail industry has experienced consolidation and other ownership changes. In the future, retailers may further consolidate, undergo restructurings or reorganizations, realign their affiliations or reposition their stores’ target market. These developments could result in a reduction in the number of stores that carry our products, increased ownership concentration within the retail industry, increased credit exposure, and increased retailer leverage over their suppliers. These changes could impact our opportunities in the market and increase our reliance on a smaller number of large customers.

| 15 |

We are subject to risks related to our dependence on the strength of retail economies in various parts of the world and our performance may be affected by general economic conditions and the current global financial crisis.

Our business depends on the strength of the retail economies in various parts of the world, primarily in North America, Europe and to a lesser extent, Asia, Central and South America, which have recently deteriorated significantly and may remain depressed, or be subject to further deterioration, for the foreseeable future. These retail economies are affected primarily by factors such as consumer demand and the condition of the retail industry, which, in turn, are affected by general economic conditions and specific events such as natural disasters, terrorist attacks, and political unrest. The impact of these external factors is difficult to predict, and one or more of the factors could adversely impact our business, results of operations, and financial condition.

Purchases of many consumer products are discretionary and tend to be highly correlated with the cycles of the levels of disposable income of consumers. As a result, any substantial deterioration in general economic conditions could adversely affect consumer discretionary spending patterns, our sales, and our results of operations. In particular, decreased consumer confidence or a reduction in discretionary income as a result of unfavorable macroeconomic conditions may negatively affect our business. If the current macroeconomic environment persists or worsens, consumers may reduce or delay their purchases of our products. Any such reduction in purchases could have a material adverse effect on our business, financial condition, and results of operations.

Changes in the retail industry and markets for consumer products affecting our customers or retailing practices could negatively impact existing customer relationships and our results of operations.

We sell our products to retailers, including sporting goods and specialty retailers, as well as direct to consumers. A significant deterioration in the financial condition of our major customers could have a material adverse effect on our sales and profitability. We regularly monitor and evaluate the credit status of our customers and attempt to adjust sales terms as appropriate. Despite these efforts, a bankruptcy filing by a key customer could have a material adverse effect on our business, results of operations, and financial condition.

In addition, as a result of the desire of retailers to more closely manage inventory levels, there is a growing trend among retailers to make purchases on a “just-in-time” basis. This requires us to shorten our lead time for production in certain cases and more closely anticipate demand, which could in the future require us to carry additional inventories.

We may be negatively affected by changes in the policies of our retailer customers, such as inventory destocking, limitations on access to and time on shelf space, use of private label brands, price demands, payment terms, and other conditions, which could negatively impact our results of operations.

There is a growing trend among retailers in the U.S. and in foreign markets to undergo changes that could decrease the number of stores that carry our products or increase the concentration of ownership within the retail industry, including:

| · | consolidating their operations; |

| · | undergoing restructurings or store closings; |

| · | undergoing reorganizations; or |

| · | realigning their affiliations. |

These consolidations could result in a shift of bargaining power to the retail industry and in fewer outlets for our products. Further consolidations could result in price and other competition that could reduce our margins and our net sales.

Seasonality and weather conditions may cause our operating results to vary from quarter to quarter.

Sales of certain of our products are seasonal. Sales of our outdoor recreation products such as carabiners, harnesses, and related climbing equipment products increase during warm weather months and decrease during winter, while sales of our apparel line and winter sports equipment such as our POC helmets and our skis, boots, bindings, and related ski equipment increase during the cold weather months and decrease during summer. Weather conditions may also negatively impact sales. For instance, milder temperatures could prevent the formation of ice, which may negatively affect demand for our ice climbing products, and mild winter weather with less snowfall may negatively impact sales of our winter sports products. These factors could have a material adverse effect on our business, results of operations, and financial condition.

| 16 |